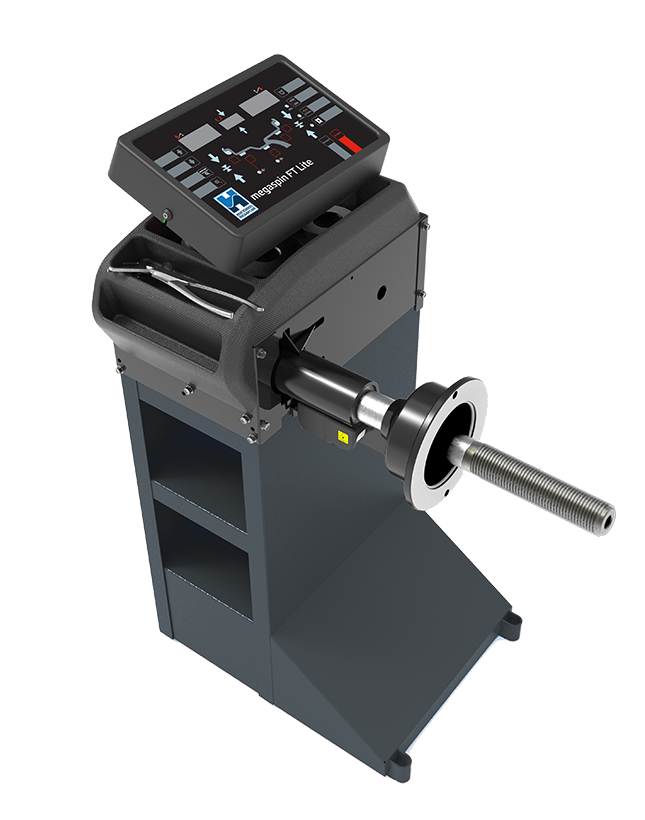

megaspin FT Lite

Versatile Wheel Balancer for Balancing Wherever You Need It

Hofmann megaspin FT Lite is the automatic balancing machine ideal for mobile service, but particularly suitable for workshops with space constraints, due to its extremely small size. The Megaspin Fast Touch transforms the wheel balancing process by integrating a laser pointer and line laser. These lasers, combined with the movement of the wheel, measure the distance and diameter of the rim, while virtual sonar technology determines its width. This allows for quick and accurate detection of all the parameters necessary to identify wheel imbalance. Fast Touch technology eliminates the need for traditional gauges, improving comfort and efficiency while reducing wear and maintenance.

Megaspin FT Lite is light, compact and flexible to balance wherever you need.

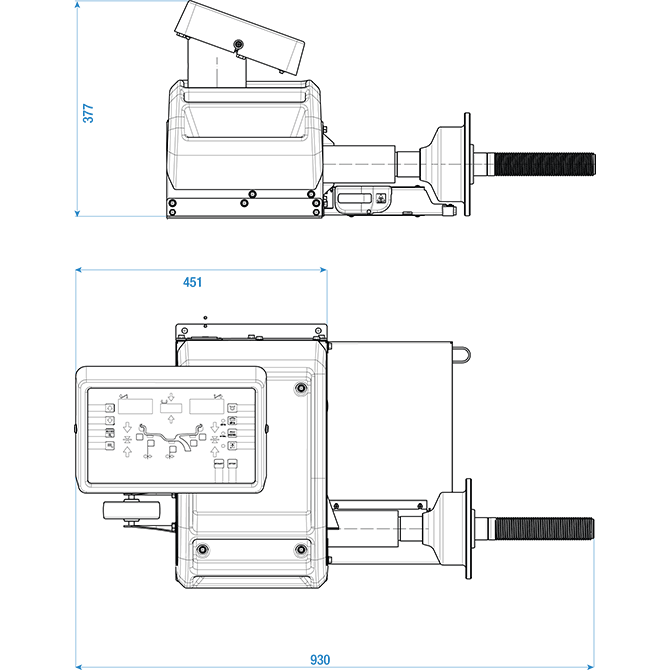

Technical data

| Single phase power supply | 230V/1ph/50-60 hz |

| 115V/1ph/50-60 Hz | |

| Max. absorbed power | 0,65 kW |

| Balancing speed | 100 rpm |

| Measurement spin time for 15 kg (33 lb) wheel | 4,7 s |

| Measurement uncertainty | ± 1 g |

| Resolution | 1 g |

| Avarage noise | < 70 dB (A) |

| Rim width setting range | 1.5” ÷ 20” / 40 ÷ 510 mm |

| Rim diameter setting range | 10” ÷ 30” / 265 ÷ 765 mm |

| Max. wheel weight | < 75 kg |

| Machine weight | 30 kg |

Accessories

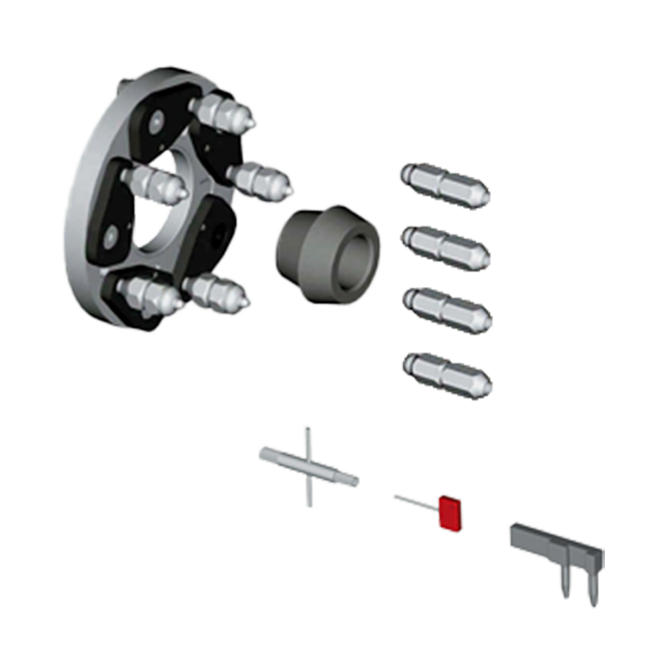

GLM40 kit for M220 without wheel guard

Quick locknut with handwheel GLM40, sleeve and ring.

3 cones kit

Ø 45÷110 mm, pincer-hammer and 60g counterweight.

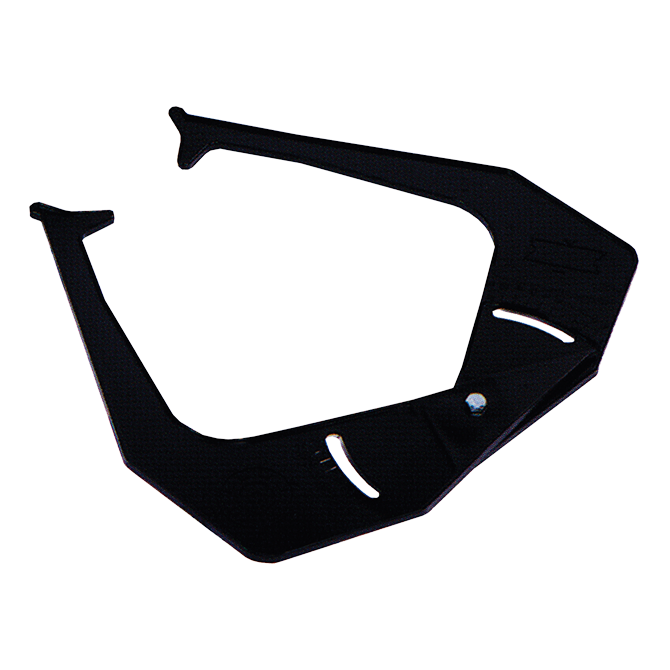

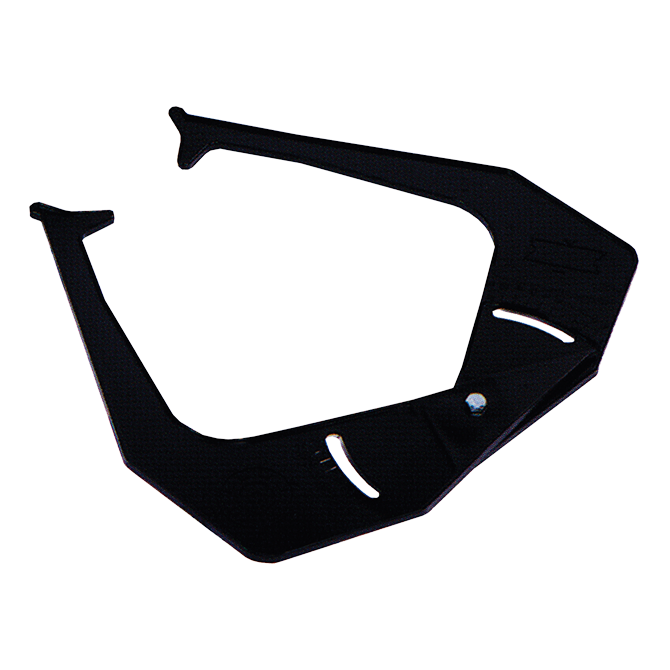

Width gauge

Width gauge.

Baseplate

Extremely compact baseplate ideal for installation in workshops with limited space or on van for mobile service.

Wheel kit

Kit di 2 wheels and screws for baseplate.

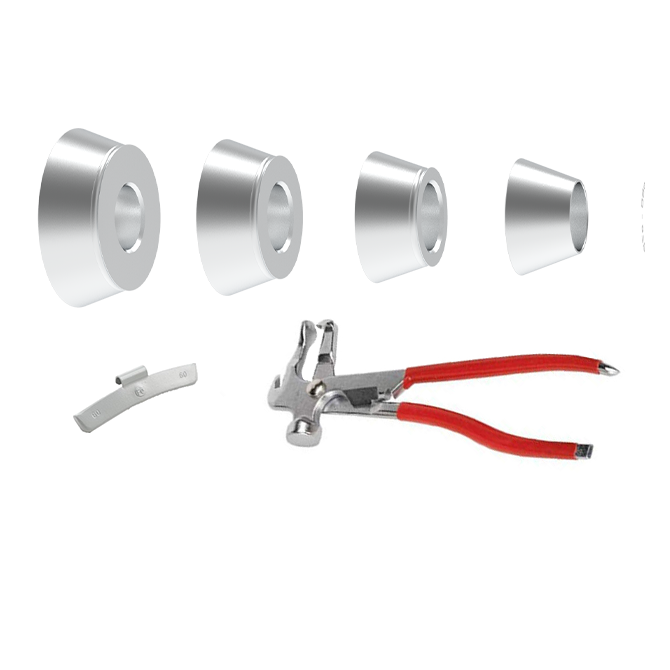

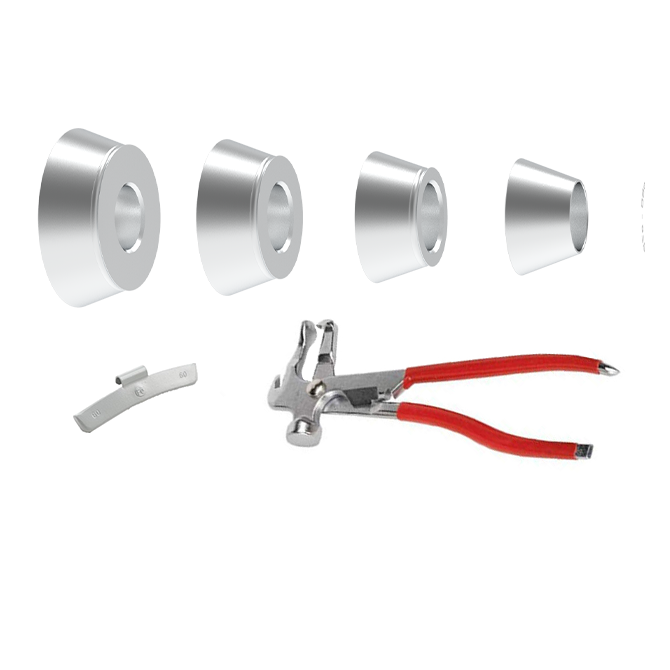

4 cones kit

Set of 4 cones Ø 45÷110 mm, counterweight 60 g and pincers hammer.

Kit VL/2+GG+G40

Kit composed of VL/2 cone, GG and G40 discs. Recommended for Ford pick-up and other 4-wheel drive vehicles (97-180mm).

MT2 cone Ø 40

Stepped cone for German cars Porsche, Audi, Opel, Volkswagen, BMW, Smart (Ø 56,5 / 57 / 66,5 / 72,5 mm centre hole).

UH20/2 Ø 40

Universal adapter for wheels with 3, 4, 5, 6 holes (Ø 95-120 mm pitch circle). Complete with high precision back centering double cone for wheels with/without central holes (Renault, Peugeot and Citroën).

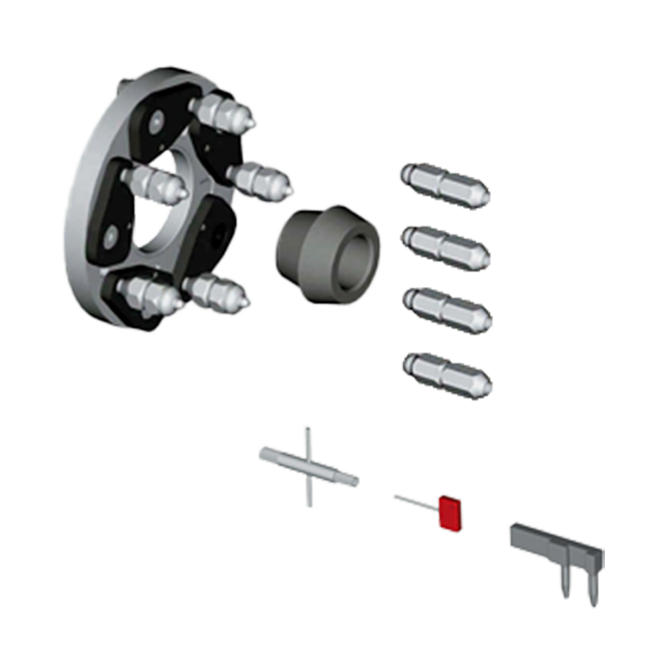

SRU 345

Universal stud adapter for all 3, 4, 5 and 6 hole rims. Infinitely adjustable bolt circle from 75 to 210 mm. Supplied with short and long clip-on studs, for different rim types.

RMC20/mot/2

Universal centering adapter for motorcycles and scooter wheels. For flanged wheels and sctooter wheels: high precision back centering cone. For wheels with bearing (inner hole Ø 15÷35

mm): haulage arm dynamically balanced.

GLM40 kit for M220 without wheel guard

Quick locknut with handwheel GLM40, sleeve and ring.

3 cones kit

Ø 45÷110 mm, pincer-hammer and 60g counterweight.

Width gauge

Width gauge.

Baseplate

Extremely compact baseplate ideal for installation in workshops with limited space or on van for mobile service.

Wheel kit

Kit di 2 wheels and screws for baseplate.

4 cones kit

Set of 4 cones Ø 45÷110 mm, counterweight 60 g and pincers hammer.

Kit VL/2+GG+G40

Kit composed of VL/2 cone, GG and G40 discs. Recommended for Ford pick-up and other 4-wheel drive vehicles (97-180mm).

MT2 cone Ø 40

Stepped cone for German cars Porsche, Audi, Opel, Volkswagen, BMW, Smart (Ø 56,5 / 57 / 66,5 / 72,5 mm centre hole).

UH20/2 Ø 40

Universal adapter for wheels with 3, 4, 5, 6 holes (Ø 95-120 mm pitch circle). Complete with high precision back centering double cone for wheels with/without central holes (Renault, Peugeot and Citroën).

SRU 345

Universal stud adapter for all 3, 4, 5 and 6 hole rims. Infinitely adjustable bolt circle from 75 to 210 mm. Supplied with short and long clip-on studs, for different rim types.

RMC20/mot/2

Universal centering adapter for motorcycles and scooter wheels. For flanged wheels and sctooter wheels: high precision back centering cone. For wheels with bearing (inner hole Ø 15÷35

mm): haulage arm dynamically balanced.