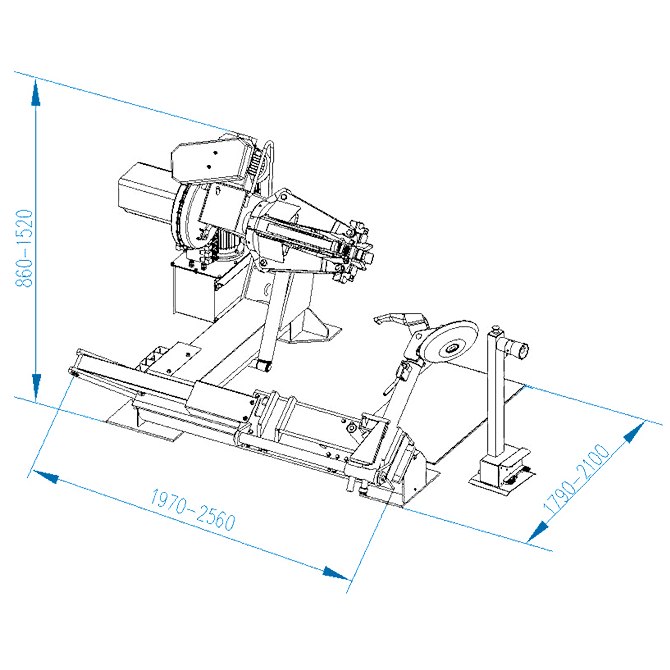

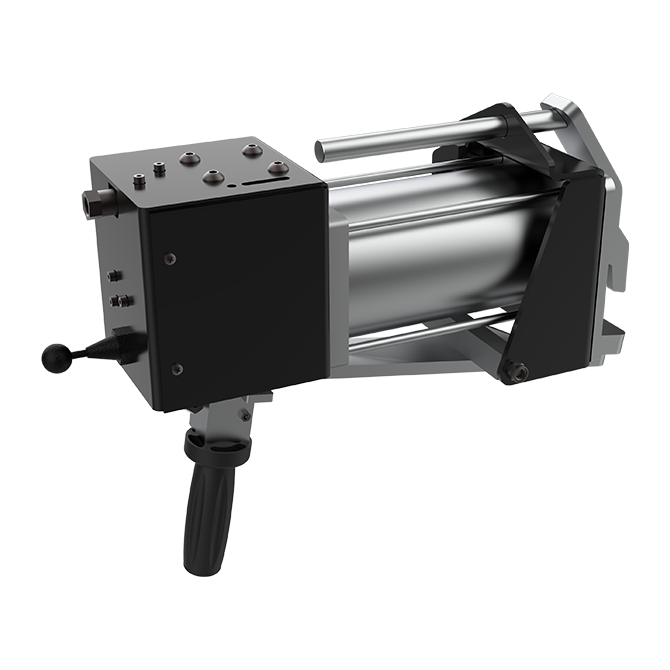

megamount T46

Electro-Hydraulic Tyre Changer for Truck, Bus and Agriculture Wheels up to 46"

Megamount T46 is the electro-hydraulic universal tyre changer designed for truck, bus, and agricultural vehicle wheels ranging from 14” to 46”, extendable up to 56” with optional extensions. It features a self-centering chuck with four jaws and five clamping points, ensuring a secure grip on all rim types. The high-pressure hydraulic circuit, adjustable up to 130 bar, allows efficient handling of steel and alloy rims, while the spindle operates at two speeds in both directions for optimal performance. The tool-holder arm is manually adjustable in direction and inclination, allowing quick selection of the appropriate tool for bead-breaking, extraction, and tyre mounting. A quick unlocking system ensures smooth and efficient operation changes. The manual sliding mechanism along the tool-holder carriage enables precise positioning on both the inner and outer sides of the rim. The low-voltage portable control unit is easily movable and features an intuitive layout of levers, buttons, and pedals to prevent accidental operations.

Technical data

| Clamping capacity | 14” - 46” (56” w/extensions) |

| Max. wheel weight | 1500 kg |

| Max. wheel width | 1.065 mm (42”) |

| Max. wheel diameter | 2.300 mm (90,5”) |

| Hydraulic unit motor | 1.1 kW |

| Chuck motor | 1,3 - 1,8 kW |

| Operating pressure | 0÷130 bar |

| Bead breaker force | 2690 Kgf |

| Gross weight | 816 Kg |

Accessories

Lever

Bead lifting lever.

Bead lever

Bead lever.

Clamp

Aluminum rim clamp.

Bead pressor

Bead pressor for agricultural/earth moving wheels.

Clamping extensions

4 clamping extension up to 56”.

Protections for aluminum rims

Set of 4 plastic protections for aluminum rims.

Ring protection

Ring protection for 22,5” alloy rim.

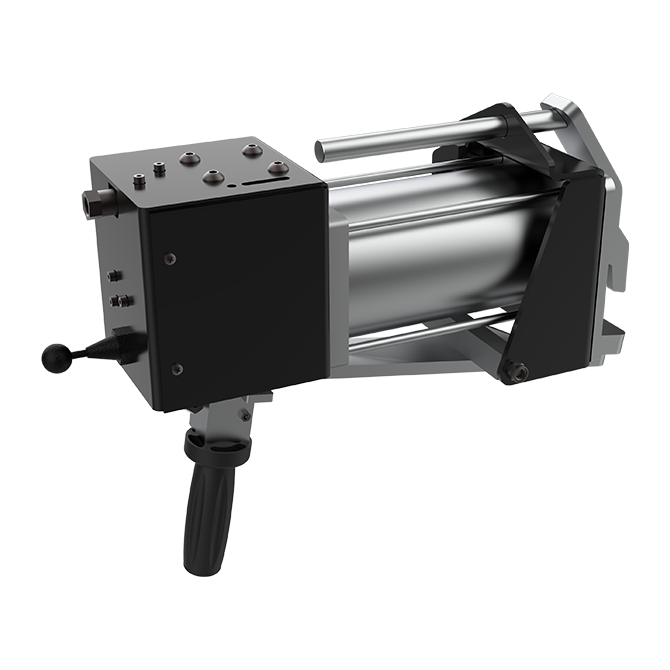

Roller

Roller for tubeless wheels.

Lever

Bead lifting lever.

Bead lever

Bead lever.

Clamp

Aluminum rim clamp.

Bead pressor

Bead pressor for agricultural/earth moving wheels.

Clamping extensions

4 clamping extension up to 56”.

Protections for aluminum rims

Set of 4 plastic protections for aluminum rims.

Ring protection

Ring protection for 22,5” alloy rim.

Roller

Roller for tubeless wheels.