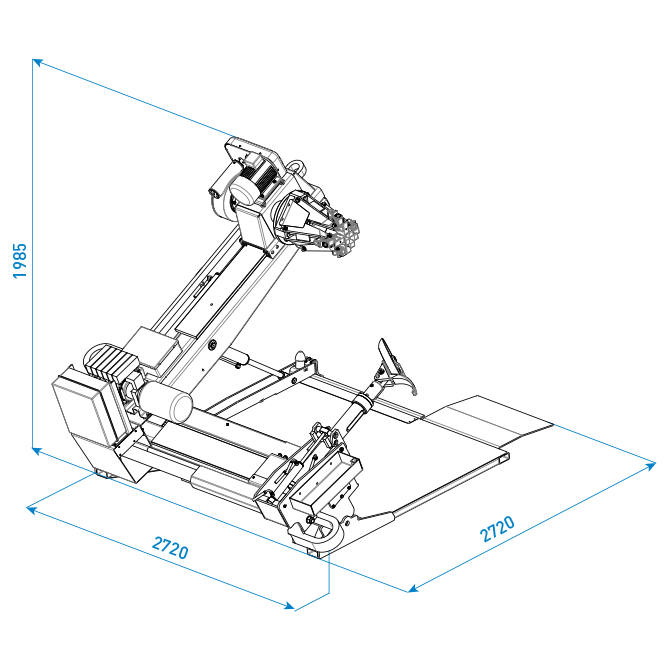

megamount 2-60T

Super-automatic Tyre Changer for Wheels of Heavy Vehicles up to 60"

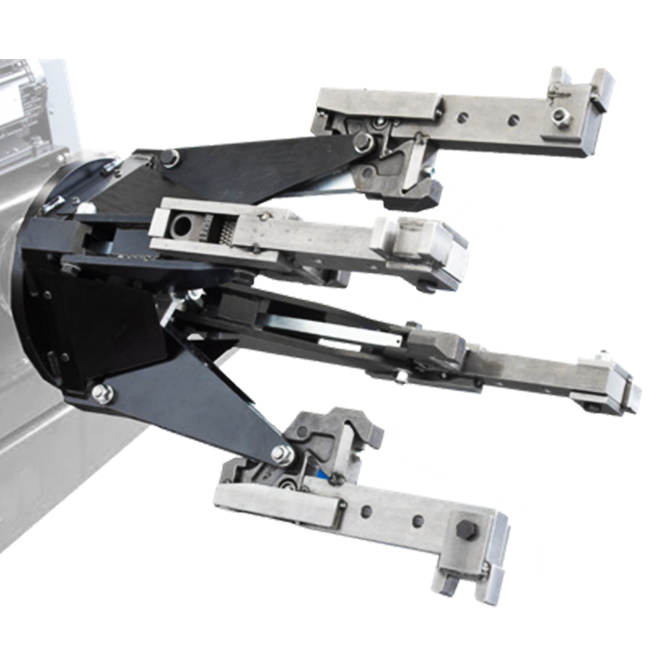

The MM2-60T is the super-automatic tyre changer with synchronized movement of the carriages. It features a self-centering chuck with four jaws that provide a secure grip on rims and operates through a high-pressure hydraulic circuit (up to 140 bar). The fully automatic tool-holder arm ensures precise positioning, allowing for leverless operation and faster mounting/demounting while protecting the tyre and rim. The portable low-voltage control unit is designed for easy movement within the workspace and includes ergonomically arranged levers, buttons, and pedals to minimize operator errors. It also controls the translational movement of the tool-holder carriage and includes a stand-by function and emergency button for added safety. The spindle operates at two rotation speeds in both directions, ensuring adaptability to different wheel types.

For additional convenience, the Megamount 2-60T is available in a version with radio-controlled commands (2-60TR), offering even greater flexibility in operation.

Technical data

| Clamping capacity | 14” ÷ 42” (14” ÷ 60” ext.) |

| Max wheel diameter | 2700 mm (106”) |

| Max wheel width | 1500 mm (59”) |

| Max wheel weight | 2500 kg |

| Max bead-breaking power | 30.000 N |

| Speed of rotation | 4.5 - 9 rpm |

| 3-Phase motor | 2.2 - 3 kW (2 hp) |

| Power supply | 400 V/3/50Hz |

| Net weight | 1550 kg |

Accessories

Clamp

Aluminum rim clamp.

Lever

Bead lifting lever.

60″ extensions

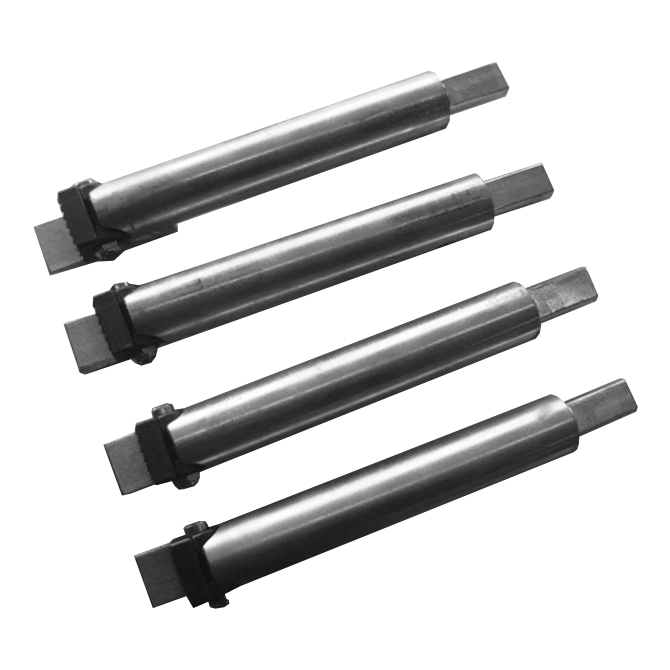

4 clamping extensions up to 60”.

Bead pressor

Bead pressor for agricultural/earth moving wheels.

Protections for aluminum rims

Set of 4 plastic protections for aluminum rims.

Ring protection

Ring protection for 22,5” alloy rim.

Caterpillar adaptor

Caterpillar clamping adaptors kit.

Adaptor for internal hole

1x adaptor for internal hole 100 mm.

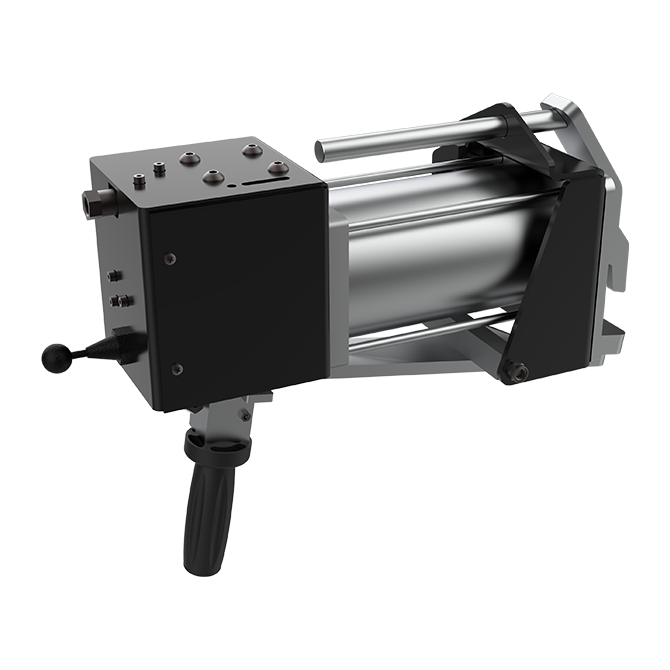

LL cylinder

LL cylinder – for leverless demounting.

Clamp

Aluminum rim clamp.

Lever

Bead lifting lever.

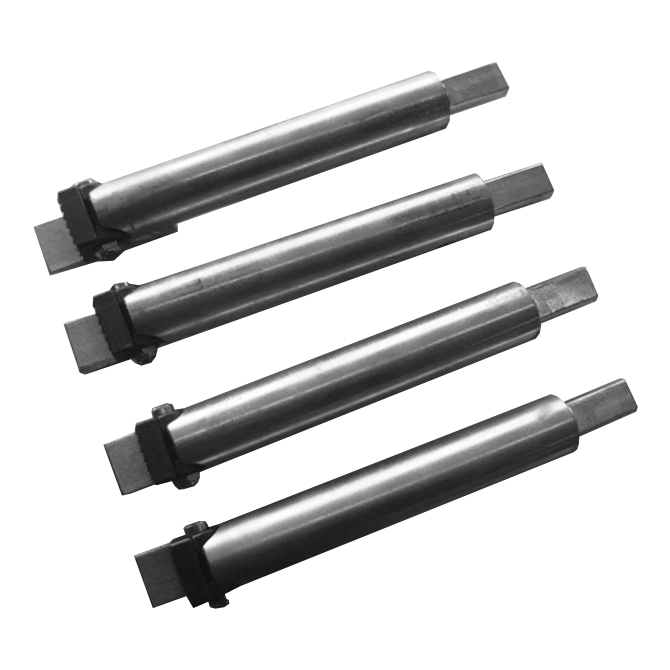

60″ extensions

4 clamping extensions up to 60”.

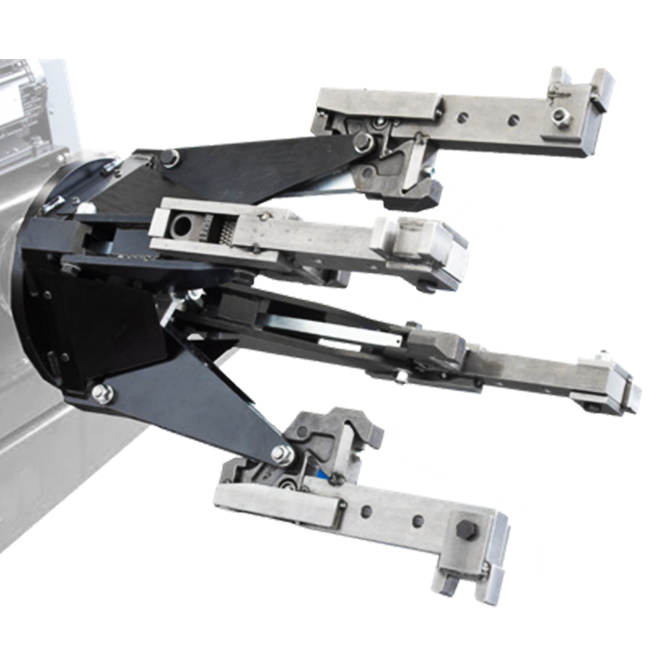

Bead pressor

Bead pressor for agricultural/earth moving wheels.

Protections for aluminum rims

Set of 4 plastic protections for aluminum rims.

Ring protection

Ring protection for 22,5” alloy rim.

Caterpillar adaptor

Caterpillar clamping adaptors kit.

Adaptor for internal hole

1x adaptor for internal hole 100 mm.

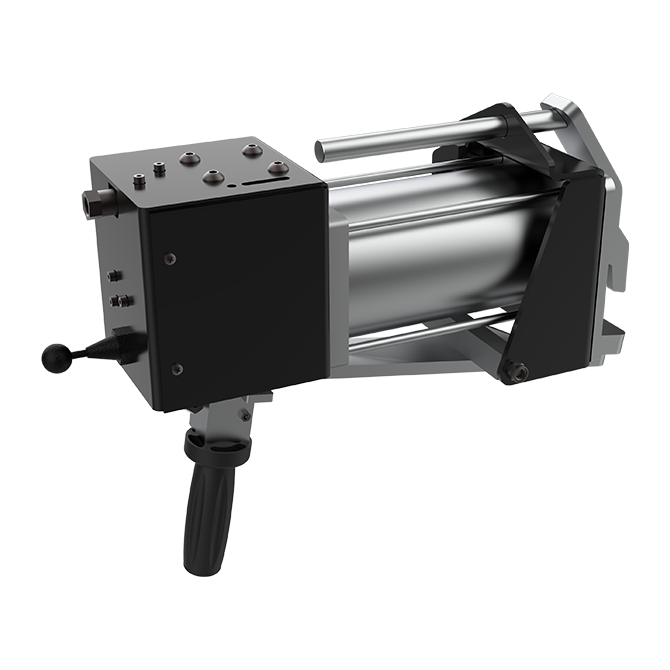

LL cylinder

LL cylinder – for leverless demounting.