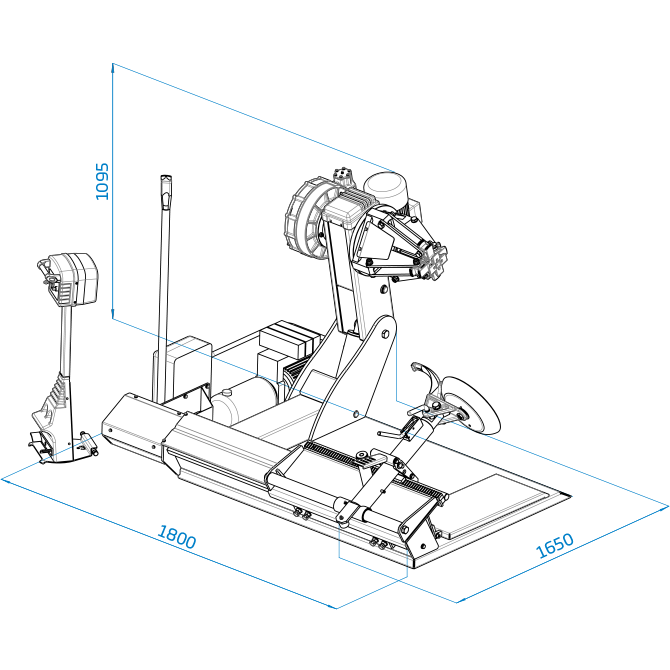

megamount 2-30T

Electro-Hydraulic Tyre Changer for Wheels of Heavy Vehicles up to 30"

The MM2-30T is the electro-hydraulic universal tyre changer designed for trucks and buses, with a clamping capacity from 14” to 30”. It features a self-centering chuck mounted on a movable spindle arm, ensuring secure clamping for various rim shapes and profiles. The hydraulic circuit allows handling of steel and alloy rims, adjustable up to 110 bar, with one-speed rotation in both directions. The tool-holder arm is manually adjustable in direction and inclination, allowing quick selection of the appropriate tool for bead-breaking, extraction, and tyre mounting. A quick unlocking system ensures fast operation changes, while the tool-holder carriage allows easy positioning on both the inner and outer sides of the rim. The low-voltage portable control unit is easily movable, with an ergonomic layout of levers, buttons, and pedals to prevent accidental operations. It also manages the translational movement of the tool-holder carriage for increased precision.

Technical data

| Clamping capacity | 10” ÷ 30” |

| Max wheel diameter | 1640 mm (65") |

| Max wheel width | 850 mm (34”) |

| Max wheel weight | 1200 kg |

| Max bead-breaking power | 25.000 N |

| Speed of rotation | 7 rpm |

| 3-Phase motor | 1.5 kW (2 hp) |

| Power supply | 400 V/3/50Hz |

| Net weight | 605 kg |

Accessories

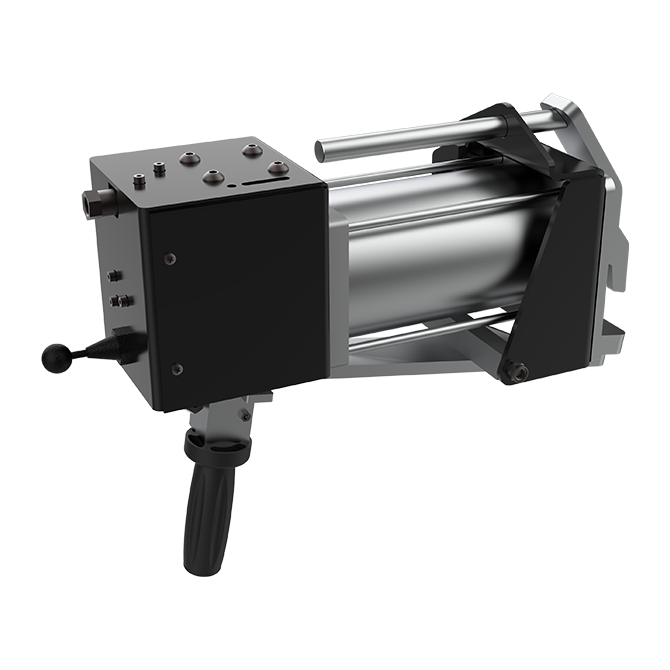

Clamp

Aluminum rim clamp.

Lever

Bead lifting lever.

Bead pressor

Bead pressor for agricultural/earth moving wheels.

Protections for aluminum rims

Set of 4 plastic protections for aluminum rims.

Ring protection

Ring protection for 22,5” alloy rim.

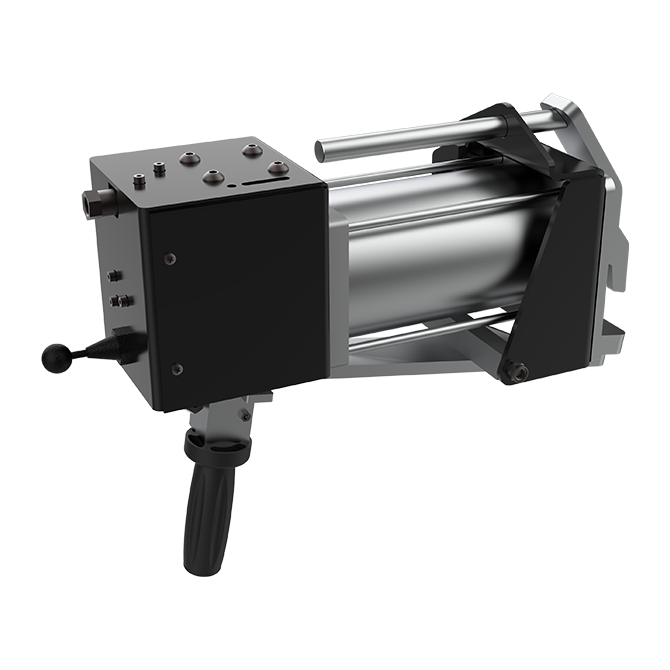

Clamp

Aluminum rim clamp.

Lever

Bead lifting lever.

Bead pressor

Bead pressor for agricultural/earth moving wheels.

Protections for aluminum rims

Set of 4 plastic protections for aluminum rims.

Ring protection

Ring protection for 22,5” alloy rim.